Automatic painting system mixed liquid / powder

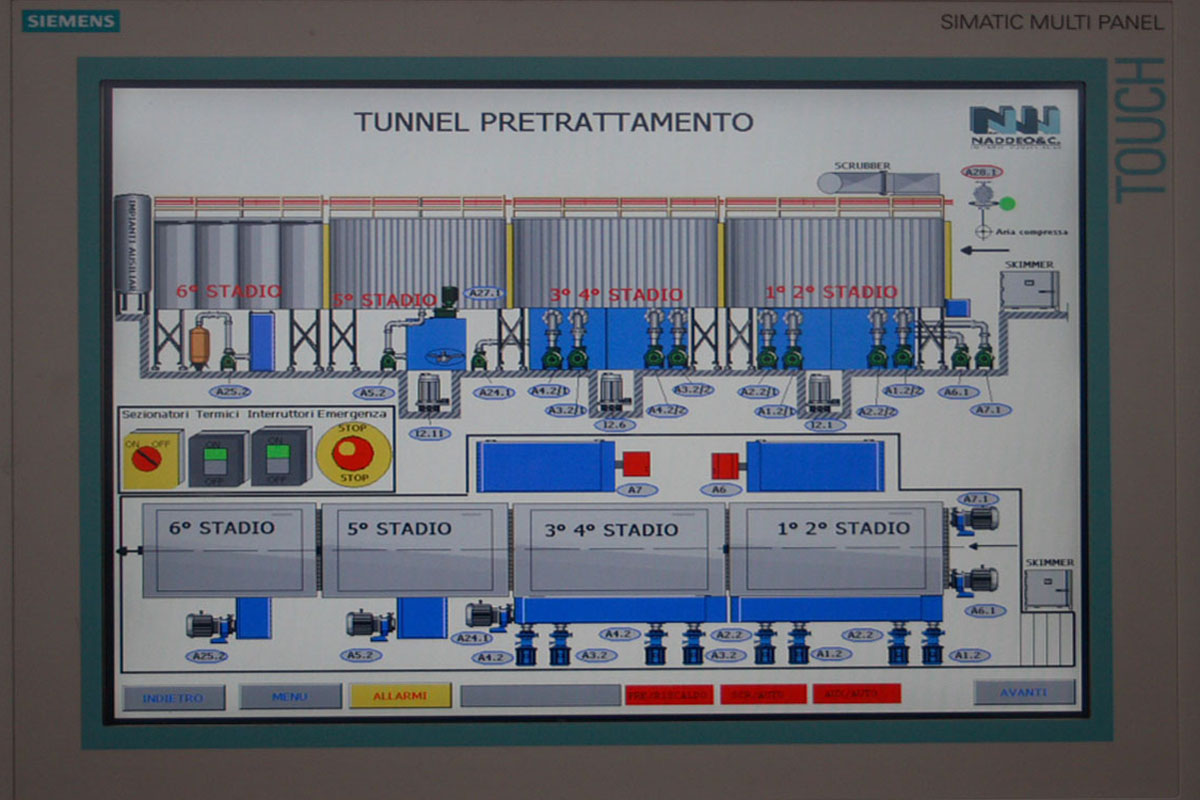

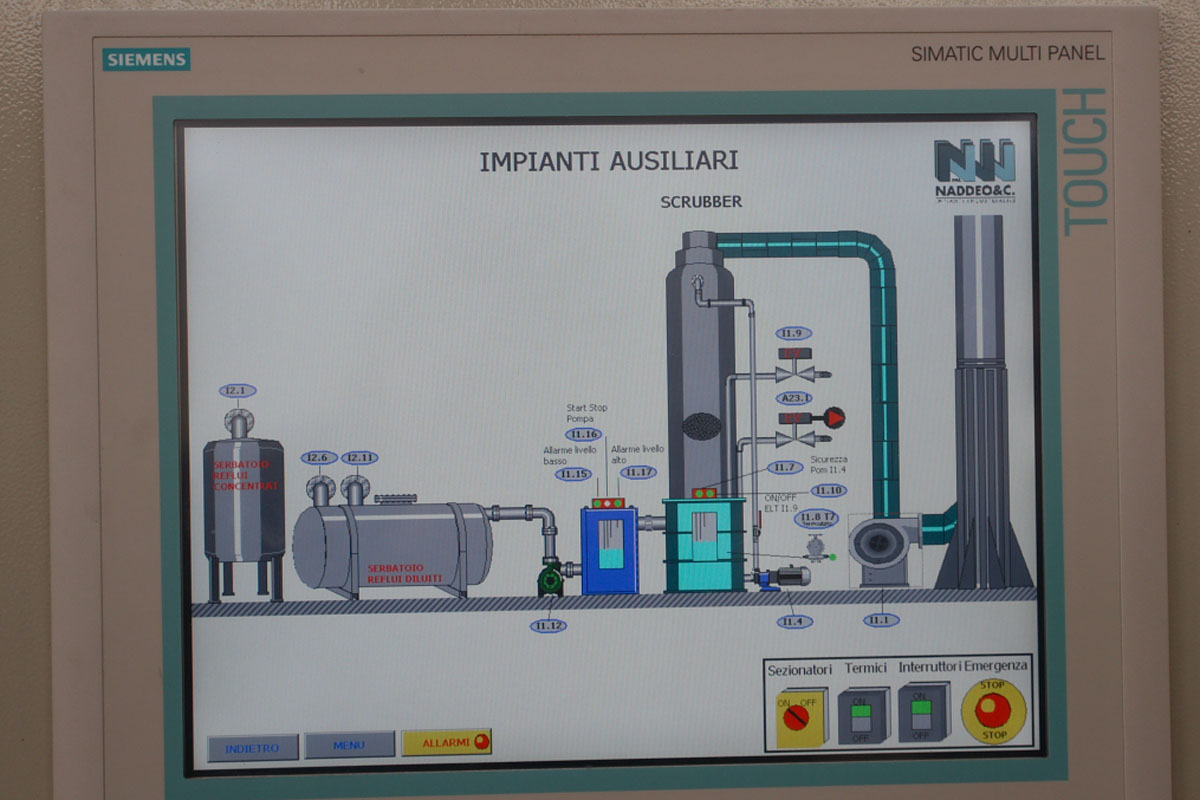

Pretreatment nanotechnology, wet on wet and powder on liquid; two powder coating booths with color changing offline and pressurized painting booth for liquids, one is drying oven and another one is curing oven. Completed with neutralization acid fume plants and industrial water purification system. Control and management through control panel with PLC, page graphics and telecontrol system with GSM card.

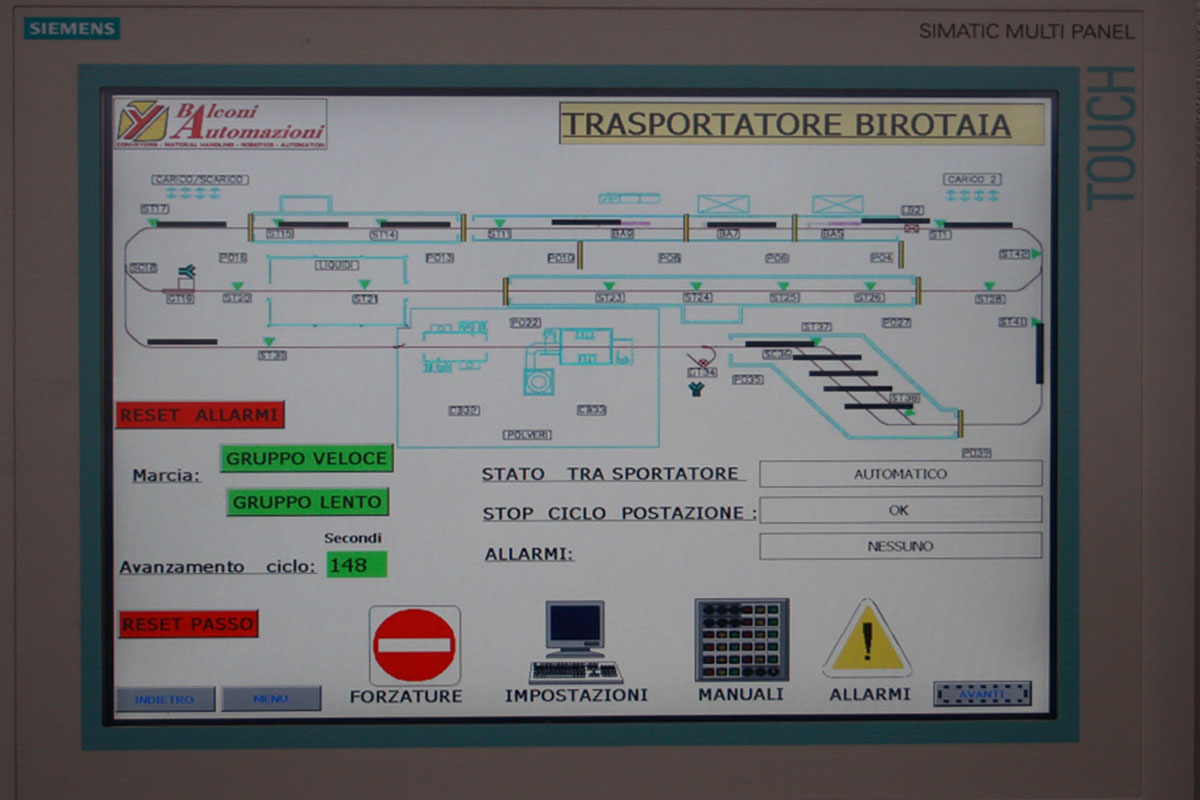

Painting system for iron and aluminum frames and fixtures completed with traditional pre-treatment with double-track conveyors handled step by step and continuously depending on the stage of painting. The drying and curing is done in ovens with open passage. The cycle consists of wet on wet painting and powder to liquid, while the painting is guaranteed by two powder paint booths with color changing off-line and liquid aspiration booth. Control and management is done through control panel with PLC programming of orders and graphics pages.

Click to see the gallery with zoomed images of the project